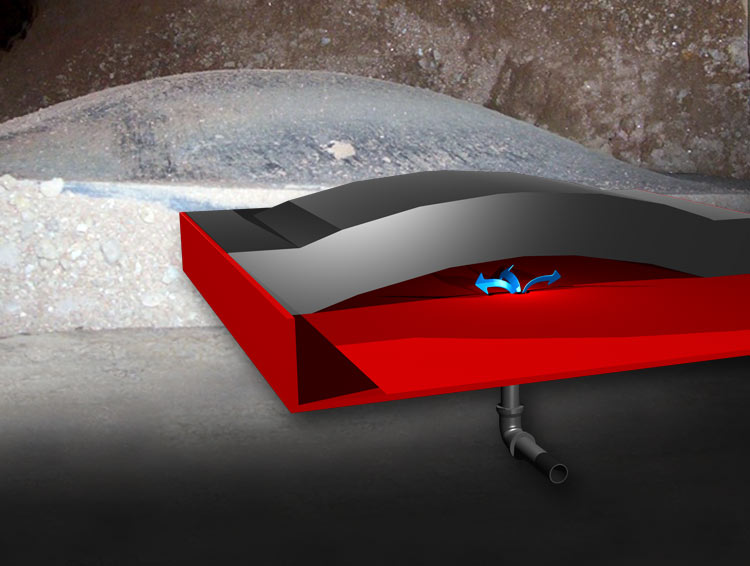

Cost effective when installed in areas in which there is severe buildup as a result of high moisture content in the material. These systems consist of custom-fit rubber liners that inflate and deflate with low-pressure air supplied through a user friendly Valley Rubber control box. The timed action keeps the liners clean and the chute free from buildup. These systems provide extensive periods of maintenance-free service in areas which were previously high maintenance.

Inflatable Rubber Liners are used primarily to keep sticky material from building up on chute walls. They are very effective at keeping chutes from plugging. The liners are custom built to fit many different applications.

Custom Solutions

- Liners can be delivered to fit various shapes, sizes, thicknesses and curvatures.

- Our rubber compounds play a major role in the cost effective performance of our liners.

- Control box cabinets can be further customized with:

- Additional air outlets

- Lighting

- Heating

- Outside controls

- Operating indicators

- Remote controls

Inflatable Liner Testing

In this video we’re testing the rubber to steel bond. Our standard high-quality manufacturing procedures were followed. The liner is 24″ x 24″ with 3″ thick rubber. Low pressure air was used to inflate the thick rubber. Normal testing procedures were followed: 15 psi for 25 seconds, every 25 seconds for 24 hours. But then “normal” testing was abandoned… Watch the video to see.