Falkville, AL- Prior to using Valley Rubber BeltSeal-Kits, operations had experienced the following issues: MSHA and EPA violations, excessive maintenance, and the inability to meet full production. Below are four illustrations demonstrating how BeltSeal-Kits and their components have provided solutions to common plant issues.

Falkville, AL- Prior to using Valley Rubber BeltSeal-Kits, operations had experienced the following issues: MSHA and EPA violations, excessive maintenance, and the inability to meet full production. Below are four illustrations demonstrating how BeltSeal-Kits and their components have provided solutions to common plant issues.

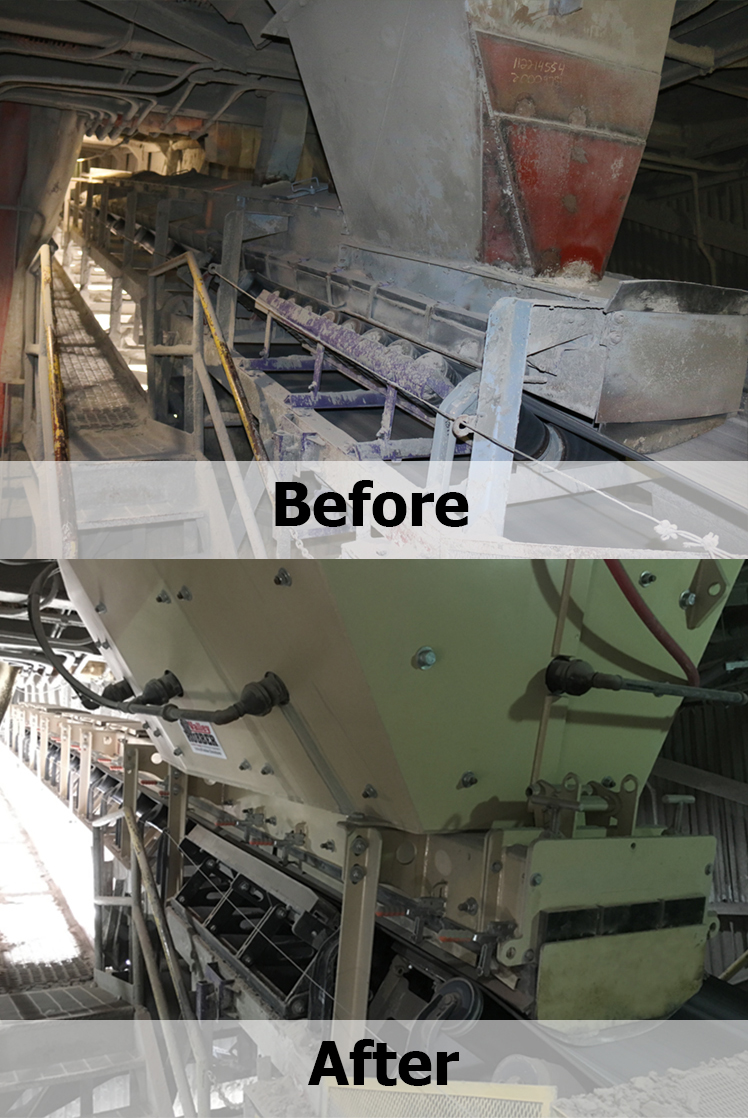

An operation’s load zone was not properly supported which allowed the belt to porpoise between the impact idlers. Significant spillage, dust and maintenance resulted from this issue. The Load Zone was running 3000TPH with two Cone Crushers at 1,100hp each, crushing 14” minus material to ¾” minus. A three-man crew spent six hours twice a week cleaning up the spillage.

Solution: Valley Rubber’s solution included adding BeltSeal Clamps with DoubleLip-DustSeal skirting and Impact Idlers that are spaced tighter together. Adjustable BeltStabilizer Brackets and Bars were installed between the troughing idlers. After the BeltSeal-Kit and TailSeal-Kit were installed, the three-man cleanup crew only came once every two weeks.

Steel liners in a Latin American operation only lasted 45 days. There was an increased cost-per-ton, along with spillage, dust and noise.

Solution: Rubber-Ceramic Liners were installed and after fifteen months are still in operation. Canoe Liners simplify installation, adjustment and alignment. They are anchored to the canoe frame using T-Bolts that are embedded within the Canoe Liner.

Typical seals are sold in large rolls that are ineffective and hard to handle.

Solution: DustSeals are effective, easy to handle and are supplied in 10’ lengths. Valley Rubber offers DoubleLip and TripleLip-DustSeals that are designed to work in conjunction with our BeltSeal components.

It is common to see either a piece of conveyor belt bolted to the rear of the canoe, or a slab of rubber bolted in the same fashion. Unable to be adjusted, these quick fixes are time consuming and rarely maintained, causing continued spillage and dust issues.

The previous system pictured resulted in costly fines, excessive maintenance, loss of production and structural weight load concerns due to spillage.

Solution: The TailSeal-Kit utilizes a system that incorporates three molded rubber blades that are adjustable using stainless steel t-handled screws. This allows for three points of contact to create a seal on the belt. Then for ease of inspection and maintenance, the system is hinged for access.

Valley Rubber can provide a customized BeltSeal-Kit built to your specifications resulting in reduced maintenance costs, increased production and a safer working environment.