Falkville, AL – A new concentrator plant was built in a Peruvian mine where an important technological improvement was introduced to aid in feeding the two concentrators. Currently 74,800 tons-per-day are conveyor-fed to the Intermediate Dome, with a projected increase to 160,000 tons-per-day.

Valley Rubber’s solution included redesigning the original Canoe Liner, including the dimensions, which reduced the number of liners along the three conveyor belts from 888 to 296 without exceeding the weight limitations for a one-person install. For every three original liners, one new Valley Rubber liner was installed in its place.

Valley Rubber’s solution included redesigning the original Canoe Liner, including the dimensions, which reduced the number of liners along the three conveyor belts from 888 to 296 without exceeding the weight limitations for a one-person install. For every three original liners, one new Valley Rubber liner was installed in its place.

The Problem

• Steel liners would fatigue and fracture under impact.

• Liners would prematurely wear due to abrasion.

• Long replacement time due to number of liners.

• Gaps between liners allowed leakage of material.

• Inadequate dust seals permitted fine material to be released into the environment.

• High cost due to replacement frequency.

In addition to correcting the problems listed above, the customer asked for the following criteria to be considered in the new Canoe Liner design:

• A single liner design to accommodate three different liner measurements.

• Integrated slotted hole to adjust liners for normal wear.

• Liner weight not exceed 20 kg.

Characteristics of Valley Rubber Canoe Liners:

• 594 mm length instead of 194 mm for faster and easier installation while eliminating spillage.

• Beveled ceramic bricks at the bottom to maximize abrasion resistance at the critical point.

• Ceramic Cylinders on top to resist impact and provide long wear life.

• 3 slot holes make it a one-person install and the liner can be adjusted for normal wear.

Results:

Results:

•In 419 days of work, only 160 Canoe Liners from Valley Rubber were replaced on all 3 conveyors (approximately 50%).

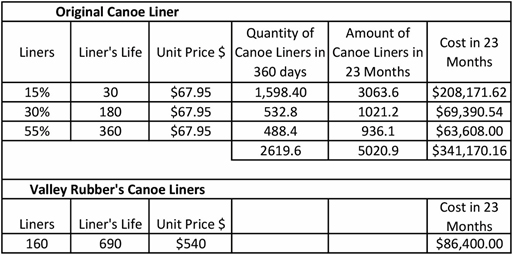

Original Canoe Liners:

• 15% were replaced every 30 days.

• 30% were replaced every 180 days.

• 55% were replaced every 360 days.

• Customer’s expectation of 44 million tons was satisfied.

•Liners were monitored in weekly inspections.

•Fewer maintenance interventions were required, and the chance of accidents was drastically reduced.

Canoe Liners Replacement Cost for a Period of 23 Months

Original Steel Canoe Liner- $341,170.16

Valley Rubber Canoe Liner- $86,400

Valley Rubber Savings: $254,770.16

Additional Beneficial Savings and Safety with Valley Rubber Canoe Liners:

• Fewer maintenance interventions- saving money.

• Shorter maintenance-reducing downtime.

• Drastic reduction of personal accidents risk- protecting people.

• Lowers overall cost-per-ton.

Transfer Point #15 Leaching Area

The canoe liners from the crushing area were initially placed as a test in transfer # 3 of the Leaching area. Although the material is a larger diameter and pass 8.350 tons per hour, the trial was successful.

In the chute discharge zone or explosion zone, where steel canoe liners lasted from 20 to 30 days, Valley Rubber liners lasted 3 months. This discharge area represents 15% of the total chute, the other 85% has not been replaced, and after 8 months they are still working well.

The Canoe Liners have been placed in transfers # 15 and # 30, and in both cases they are producing similar positive results as transfer #3.